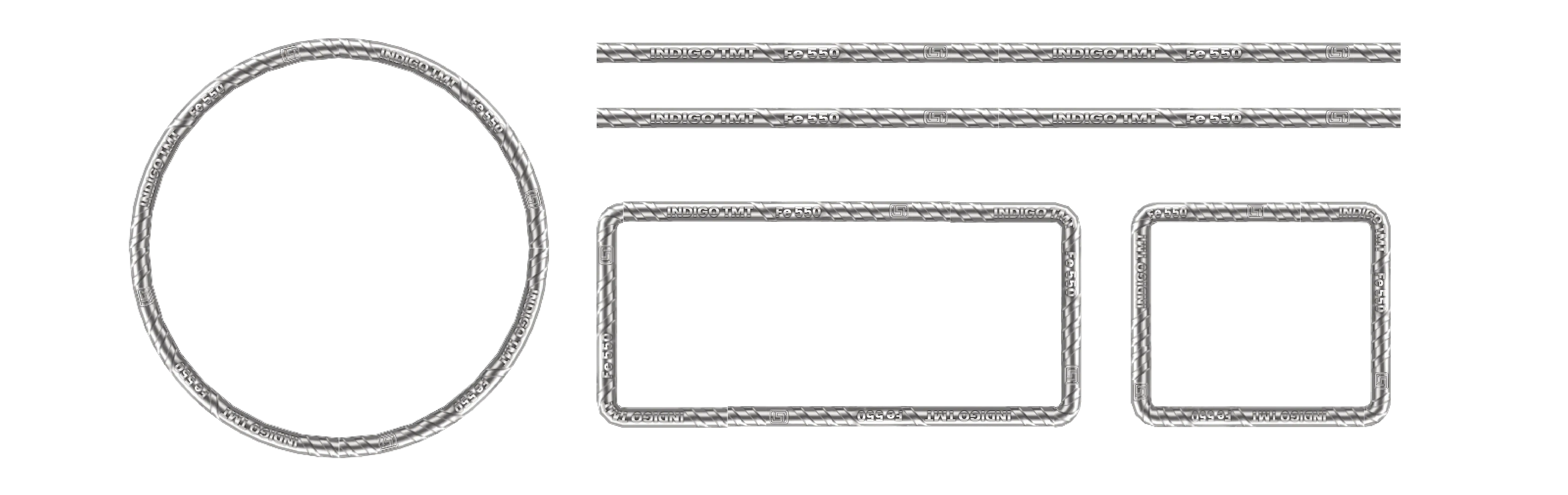

OUR PRODUCTS

550D Steel Bars

Our premium 550D TMT Steel Bars offer exceptional strength and durability for all construction applications. Engineered to meet the highest industry standards, these bars ensure structural integrity and safety for your buildings.